10 Must Have Features for Operational Audit Software

Operational Audit Software is increasingly used by companies that have significant risk exposure to the operational failures. The purpose of the software is to standardize & streamline the audit process and at the same time save people time in managing end-to end audit workflow by automating the manual activities. There are many solutions available in the market, but if you ask the users, they will have a long list of expected features. However, the top 10 features, required by most of the users are:

1️⃣ 𝙎𝙘𝙝𝙚𝙙𝙪𝙡𝙞𝙣𝙜 𝙍𝙚𝙘𝙪𝙧𝙧𝙞𝙣𝙜 𝘼𝙪𝙙𝙞𝙩𝙨: Operational audits should be done at a regular frequency or cycle. What if you can schedule recurring audit at any frequency required e.g. daily, weekly, monthly etc., like scheduling recurring meetings in calendar?

2️⃣ 𝘼𝙡𝙡𝙤𝙬𝙨 𝙗𝙧𝙚𝙖𝙠𝙞𝙣𝙜 𝙩𝙝𝙚 𝙨𝙞𝙩𝙚 𝙞𝙣𝙩𝙤 𝘼𝙧𝙚𝙖𝙨: A site has multiple areas e.g. a warehouse site may have security, parking, utility, docks, storage, packing, office areas. Shouldn’t the checkpoints be specific to each area? Does your audit software allow that and ensure no area is missed out by the auditor?

3️⃣ 𝙎𝙚𝙦𝙪𝙚𝙣𝙘𝙞𝙣𝙜 𝙩𝙝𝙚 𝘼𝙧𝙚𝙖𝙨 𝙞𝙣 𝙖 𝙇𝙤𝙜𝙞𝙘𝙖𝙡 𝙊𝙧𝙙𝙚𝙧: Imagine the auditor moving back & forth in different areas as the check points may be listed randomly. With sequencing of areas, the check points will be presented to the auditors in a logical order, saving time and avoiding any confusion.

4️⃣ 𝘾𝙤𝙣𝙩𝙧𝙤𝙡 𝙤𝙣 𝘾𝙝𝙚𝙘𝙠𝙡𝙞𝙨𝙩 & 𝙫𝙚𝙧𝙨𝙞𝙤𝙣𝙨: If you follow any QMS, you will know the importance of standardization and control of documents. Does your audit software ensure that all are using the latest version of the checklist and standards?

5️⃣ 𝘾𝙤𝙣𝙙𝙪𝙘𝙩𝙞𝙣𝙜 𝘼𝙪𝙙𝙞𝙩 𝙞𝙣 𝙈𝙤𝙗𝙞𝙡𝙚, 𝙚𝙫𝙚𝙣 𝙞𝙣 𝙊𝙛𝙛𝙡𝙞𝙣𝙚 𝙈𝙤𝙙𝙚: Many sites like warehouses, depots, fulfillment centers are located in remote areas with poor data connectivity. Also, in the cold room there may not be good data connectivity. If you don’t have an offline mode, you cannot use mobile device to conduct audits. Does your audit software work even without data or wi-fi connectivity?

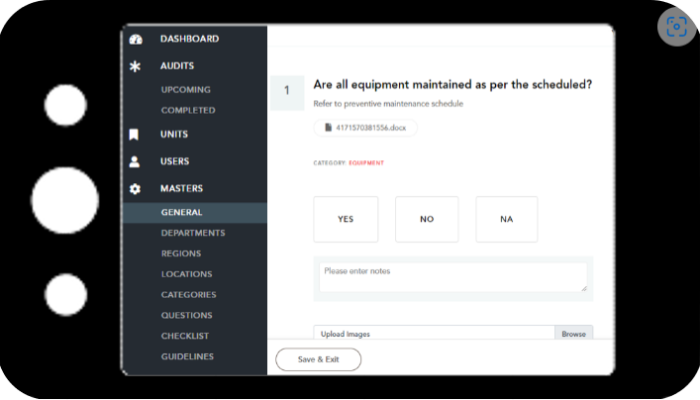

6️⃣ 𝘼𝙘𝙘𝙚𝙨𝙨 𝙩𝙤 𝙎𝙩𝙖𝙣𝙙𝙖𝙧𝙙𝙨 𝙤𝙣 𝙩𝙝𝙚 𝙜𝙤 𝙬𝙝𝙞𝙡𝙚 𝘾𝙤𝙣𝙙𝙪𝙘𝙩𝙞𝙣𝙜 𝘼𝙪𝙙𝙞𝙩: What if auditors can access the relevant standard for each check point as they are conducting the audit, without going thru the pain of checking soft or hard copies?

7️⃣ 𝘼𝙪𝙩𝙤𝙢𝙖𝙩𝙚𝙙 𝙍𝙚𝙥𝙤𝙧𝙩𝙞𝙣𝙜: In the age of social media, people don’t want to read manually written long reports. Does your software provide automated report that includes all details but yet to the point?

8️⃣ 𝙎𝙡𝙞𝙘𝙞𝙣𝙜 & 𝘿𝙞𝙘𝙞𝙣𝙜 𝙤𝙛 𝙋𝙚𝙧𝙛𝙤𝙧𝙢𝙖𝙣𝙘𝙚: Does your software allow you the slice & dice the performance by Areas, Categories, Sub-Categories, Risks or a combination of that, so that you know where the problem is?

9️⃣ 𝘼𝙨𝙨𝙞𝙜𝙣𝙢𝙚𝙣𝙩 & 𝙏𝙧𝙖𝙘𝙠𝙞𝙣𝙜 𝙤𝙛 𝘾𝙤𝙧𝙧𝙚𝙘𝙩𝙞𝙫𝙚 𝘼𝙘𝙩𝙞𝙤𝙣𝙨: What is the point of conducting audit if it doesn’t lead to timely corrective actions? Does your software allow assigning actions with timeline and then track, sends auto reminders for follow-ups?

🔟 𝙂𝙖𝙢𝙞𝙛𝙞𝙘𝙖𝙩𝙞𝙤𝙣: What if your audit software gives coins or badges based on the scores & actions taken? Wouldn’t that motivate people to go for higher standards & ratings?

SIMSA Operational Audit Software is the only platform that has all the above features. SIMSA can help you save up to 70% of the time in managing the entire workflow. Then why settle for less?